and Canada) or 72 (outside US and Canada). This course is valuable for individuals who create or interpret engineering drawings, product and gage designers process, product, and manufacturing engineers supplier quality engineers/professionals CMM operators buyers/purchasers checkers inspectors technicians and sales engineers/professionals.

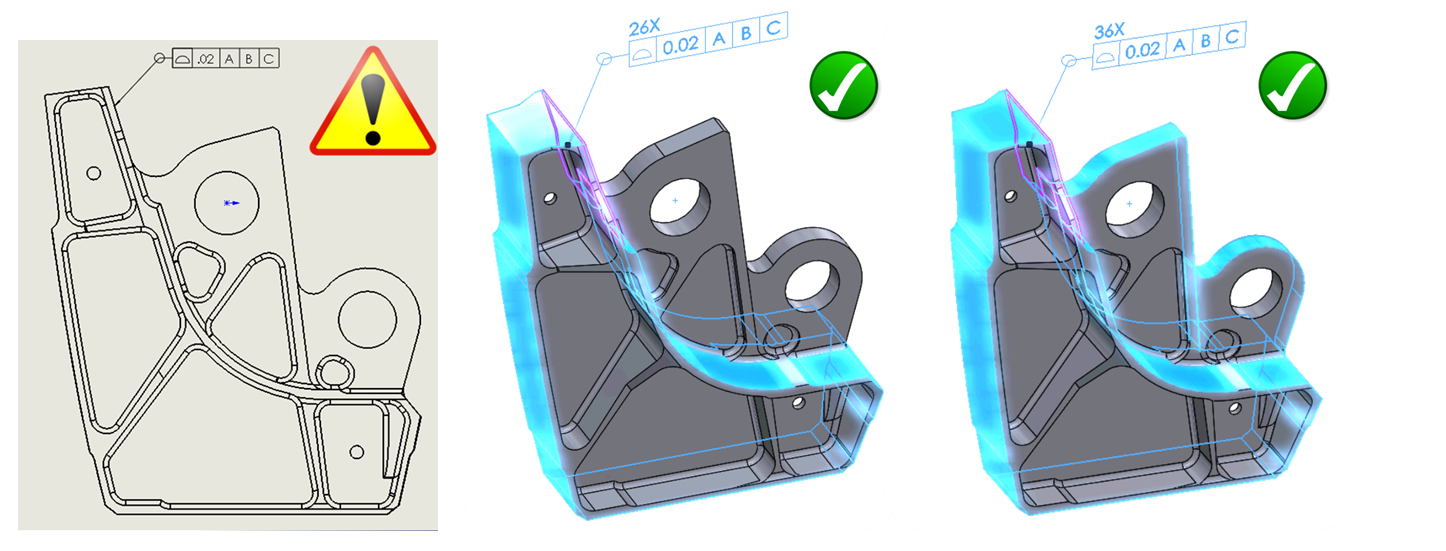

Interpret applications of datum targets, size datum features (RMB), and size datum features (MMB) geometric dimensioning and tolerancing standard, ASME Y14.52009.Interpret the various types of tolerance (flatness, circularity, cylindricity, straightness, perpendicularity, parallelism, angularity, position, runout, and profile).Describe the concepts of worst-case boundary, virtual condition, and bonus tolerance.Recognize the symbols and modifiers used in GD&T.Interpret the general dimensioning symbols.Basic Dimension - used to describe the exact size, profile. Explain why geometric tolerancing is superior to coordinate tolerancing All Around This Side of Parting Line ASME Y14.5-2009 Section 3.14.1 - To apply a.If you have a copy of ASME Y14.5 2009, refer to section 7.5.3. Describe the types of dimensions, tolerances, and notes The specific application that appears to be going on here is for positional tolerancing of coaxial features of opposed diameters.

It is governed by the technical standard ASME Y14.5-2018 (recently revised from the 2009 edition).

GD&T is a valuable tool that effectively communicates the design intent to manufacturing and inspection.

0 kommentar(er)

0 kommentar(er)